Overview of LED Flexible Transparent Film Installation

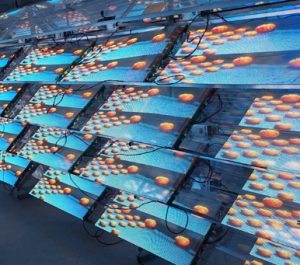

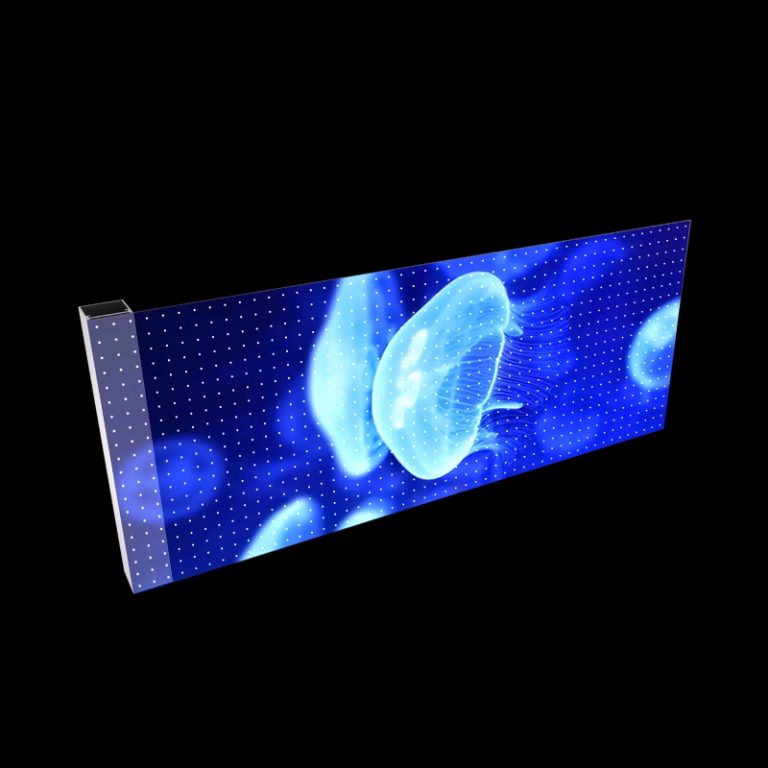

LED flexible transparent film installation is a complicated movement, which needs to be very accurate, and finished with quality. This cutting-edge technology is lightweight, transparent, flexible, and thin, and can be incorporated onto glass surfaces without using a steel frame structure. We call these LED display screens the transparent film, which has high transparency and brightness; the film is the functional carrier of the screen. Perfect for indoor solutions with aesthetics and functionality in mind along with the requirements that new technology such as VR, AR, and other displays require.

Key Features of LED Flexible Transparent Film

The LED flexible transparent film stands out due to several key features:

- High Transparency: The film boasts a transmittance rate of nearly 95%, thanks to its high transparency crystal film carrier board and PVD crystal plating process. This ensures that it does not obstruct indoor lighting or block views.

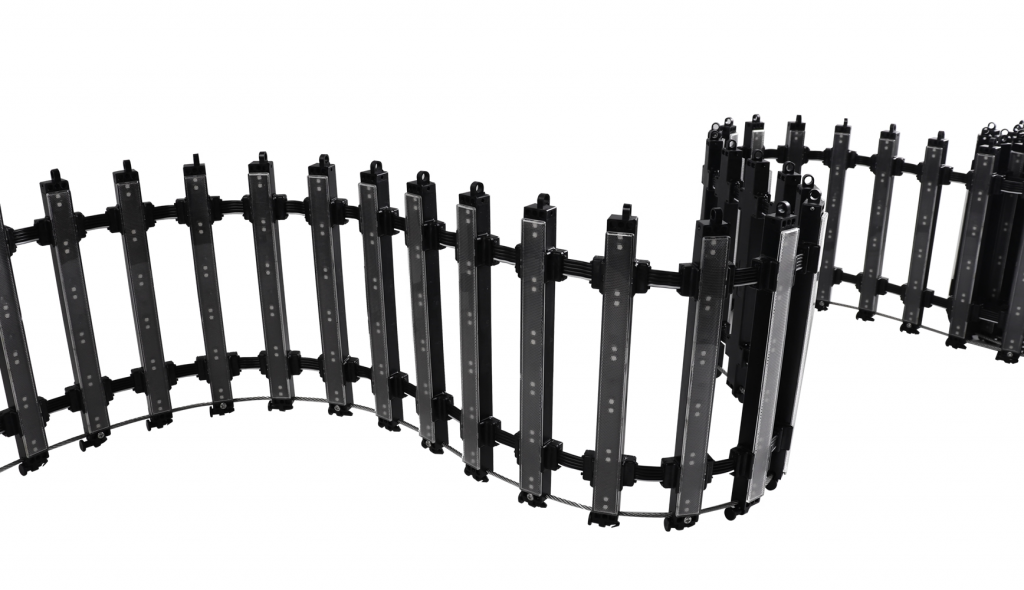

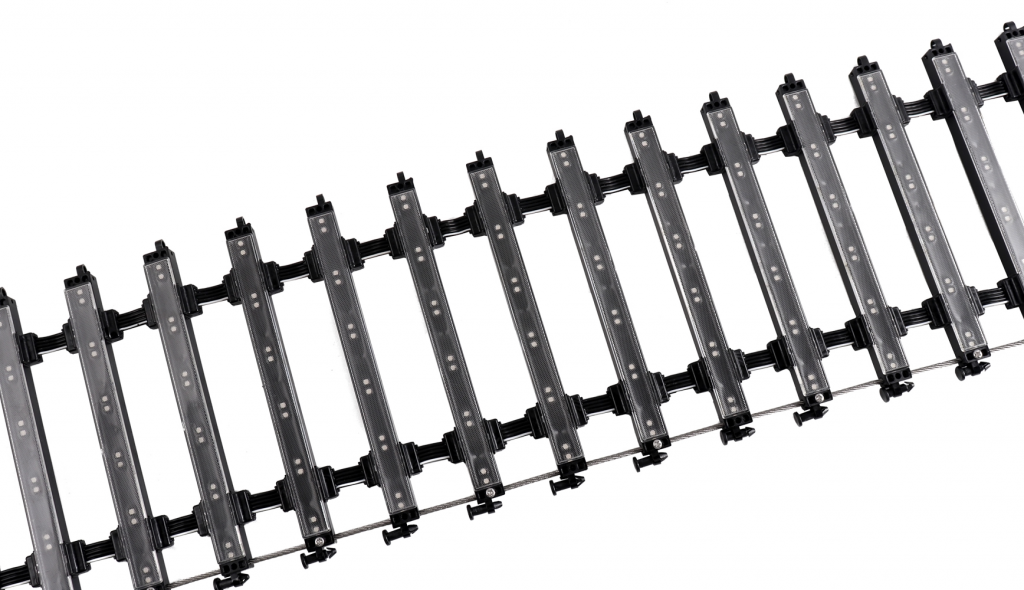

- Flexibility: The film can be folded flexibly to fit various curved surfaces, making it versatile for different installations.

- Ultra-thin Design: With a thickness of less than 2MM, the film is minimally invasive and can be directly attached to glass surfaces.

- Super Bright Display: The product achieves up to 6000 CD/m brightness while maintaining transparency, making it highly effective for advertising.

Tools and Materials Required for Installation

Before beginning the installation process, ensure you have the necessary tools and materials:

- LED flexible transparent film modules

- Cleaning supplies (e.g., microfiber cloths, glass cleaner)

- Measuring tape

- Cutting tools (e.g., precision cutters)

- Adhesive materials suitable for glass surfaces

- Alignment tools (e.g., laser level)

Preparing the Surface for Installation

Proper preparation of the surface is crucial to ensure the longevity and effectiveness of the LED flexible transparent film.

Surface Cleaning and Preparation Techniques

Clean the glass area to which the film is to be affixed. Wipe off dust or grease using a microfiber cloth and a suitable glass cleaner. Make sure it completely dries before going forward. This step is important, as any residual material can influence adhesion and quality of the display quality.

Measuring and Cutting the Film

Any way you look at it, measurement is key as always. If you have already planned the area to place the film, please take a tape measure and measure the area. Take these measurements from the film and mark them using a non-permanent marker. Strategically and cautiously trim the teaching film to size to avoid any jagged edges which can lead to unwanted issues in adhesion or check results. Use sharp cutters to cut the film while avoiding frayed edges that will compromise bond or looks.

Installing the LED Flexible Transparent Film

Once preparation is complete, proceed with installing the LED flexible transparent film.

Positioning and Aligning the Film

Align the cut flexible transparent film of LED onto the base. Align it correctly with the help of alignment tools such as a laser level with respect to adjacent holiday elements such as window frames and architectural features. The reason for this step is mainly to be able to have the same visual symmetry in the output display and have it be exactly displayed.

Adhering the Film to the Surface

After aligning, start to stick the film from one side, moving to the other. Gently press down evenly with a squeegee or something similar across the entire surface to remove air bubbles and make sure it adheres to the glass. This innovative technology works on adhesive properties, does not require any extra framing structure, saves on time and cost, and can be installed very quickly.

If the professionals follow these detailed steps to install LED flexible transparent films, they will get the best in both the visual and technology parts and can use it in different places like commercial buildings, retail spaces, or exhibition halls. When installing LED flexible transparent films, a few detailed steps need to be followed for installation professionally to achieve the perfect results to enhance visual appeal together with technological functionality in a range of situations from commercial structures to retail or exhibition halls.

Testing and Final Adjustments

Electrical Connection Setup

Once the LED flexible transparent film is fixed on the surface, the last step is to connect the wires. To get started, we should be looking for the input and output ports on the film modules. Connect the Power Ports Connect these ports with the power supply and control systems. Make sure your all connections are glued properly to avoid any expected electric shocks. To avoid electrical issues, disruptions in service, or service failures, it is essential to set up the system according to the manufacturer’s specifications.

Performance Testing and Troubleshooting

After completion of the electrical connection, perform a full performance test on the LED flexible transparent film you installed. Turn on the system and check if all the modules are evenly lit and the color is uniform on every module. Look for flickering or dead pixels that could indicate a connected module is defective. If there are irregularities, check connections, verify the power supply, and reach out to technical support when needed. Verifying the screen in this manner ensures the display is performing correctly prior to being fully deployed into the end application.

Maintenance Tips for Longevity

Routine Cleaning Practices

Using LED flexible transparent films will require regular cleaning to keep the surfaces clear and functional. Using a soft microfiber cloth, slightly dampen it with glass cleaner and gently clean the surface of the film. Do not use abrasive materials or harsh chemicals that will damage the delicate components of the display. Cleaning it up regularly can save the lens from getting trapped in the dust and not allowing transparency and visual quality.

Regular Inspection and Upkeep

Regular inspections should be arranged for the inspection of both the physical condition and performance of the LED flexible transparent film. Check for used signs like scratches or peeling edges; It needs to keep adhesion or show quality for a long period. Ensure all electrical connections are tight and free of corrosion or damage. Scheduled maintenance not only increases the life of the installation but also enables reproducible high-resolution visual displays.

XinHe Optoelectronics: Innovative Solutions in LED Technology

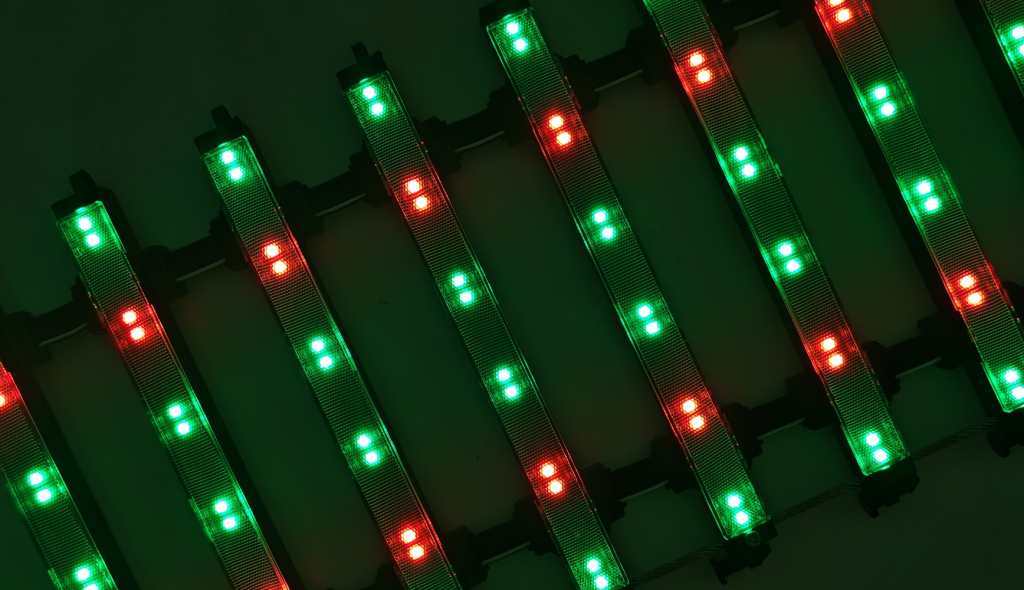

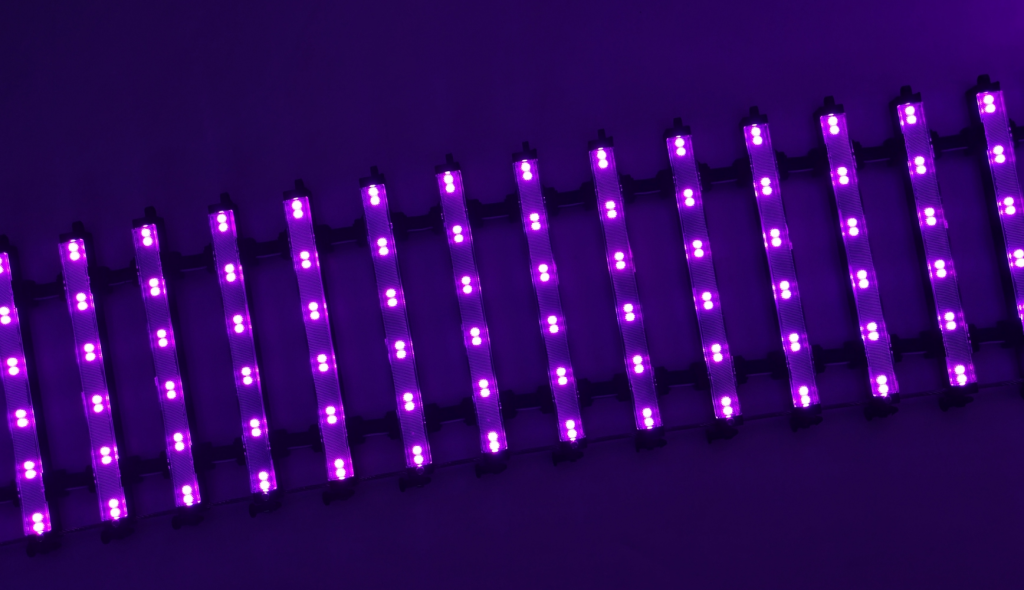

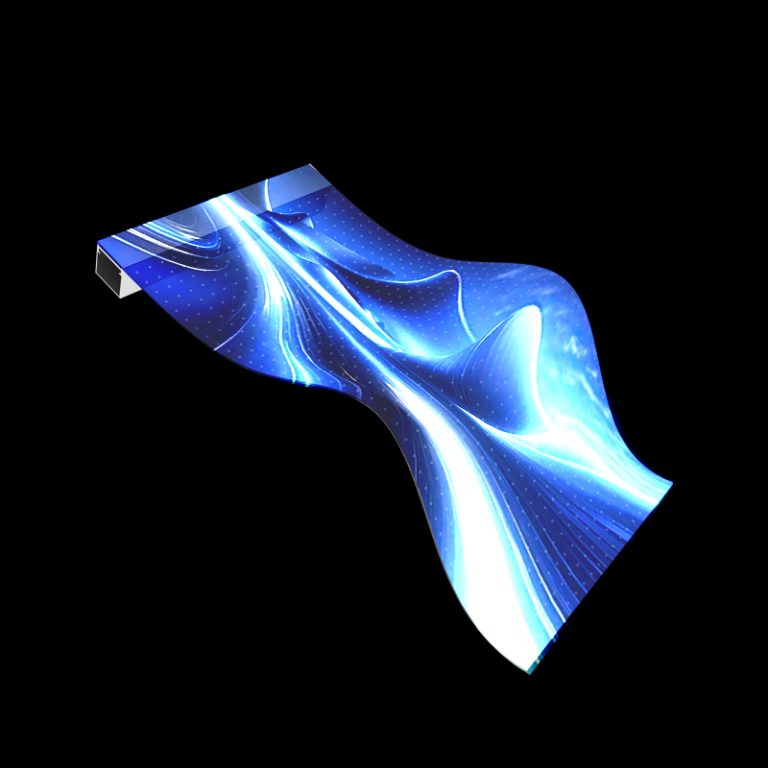

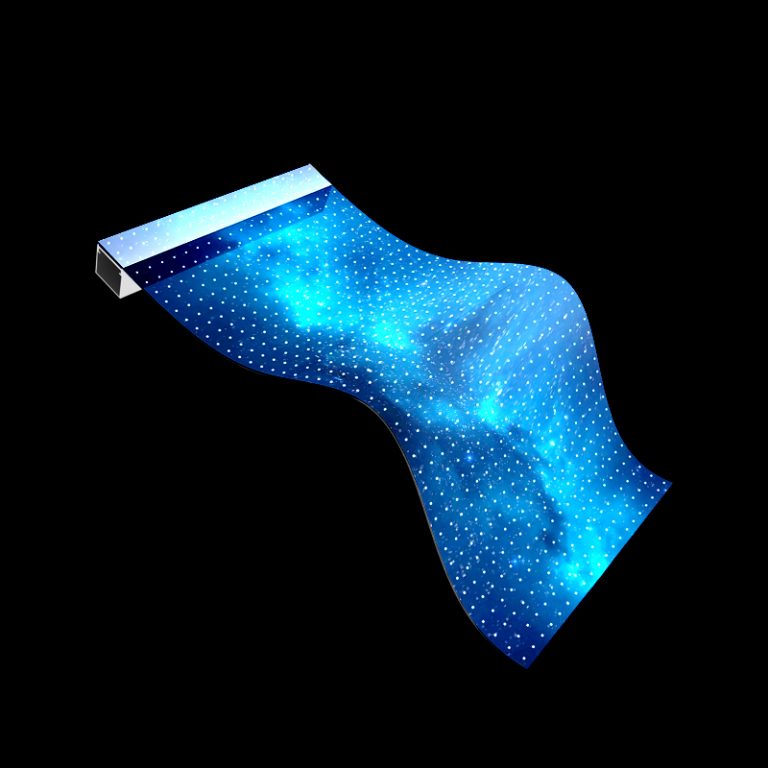

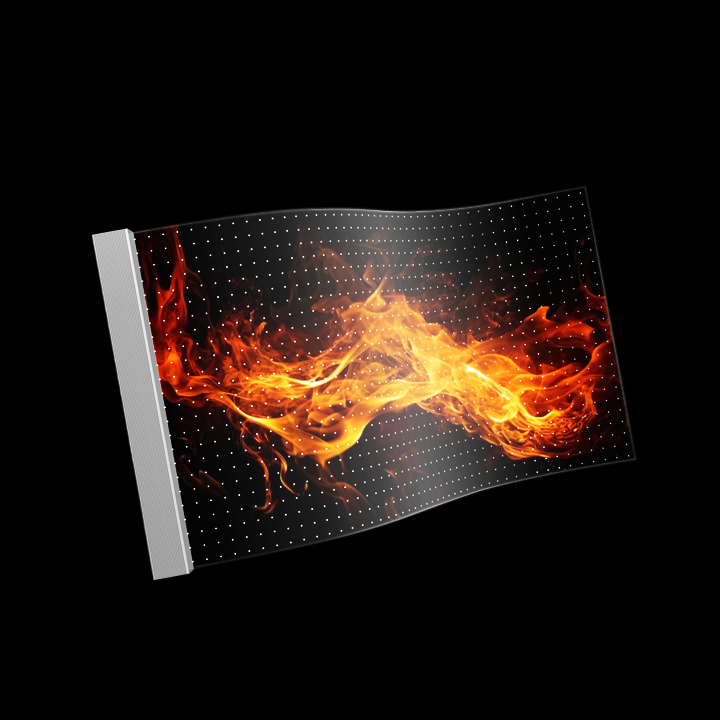

LED Flexible Transparent Film

As a manufacturer that has always made a breakthrough in LED flexible transparent film, XinHe Optoelectronics enters the forefront of science and technology. The product is able to realize high transparency, flexibility, ultra-thin profile, and bright display through this continuous advancement of design, making a critical milestone. It blends seamlessly with contemporary architectural style and does not keep views and lights away which is ideal for providing aesthetic value to commercial spaces without compromising natural light while generating powerful digital content.

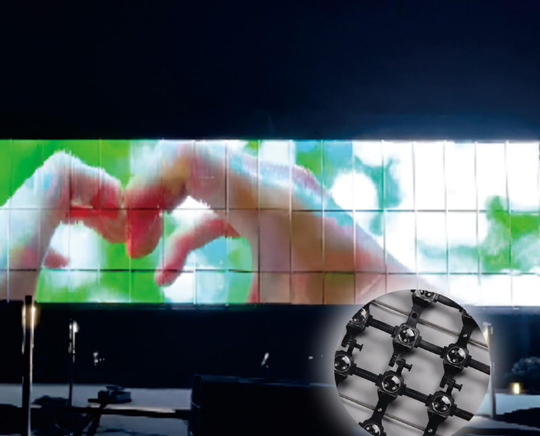

LED Video Mesh Display: Ideal Choice for Indoor and Outdoor Use

Apart from their clear films with flexibility properties, XinHe Optoelectronics also has LED video mesh displays, which offer both indoor displays and outdoor displays. These displays are rugged so they can be used in a variety of environmental conditions, along with being daylight readable. This versatility makes them ideal for widespread installations such as building facades or stadiums where dynamic visual communication is paramount.